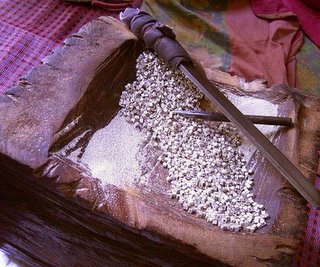

In order to make these beads, little balls of melted silver need to be cooled, and then holes are drilled to create beads. The beads are then filed down into shape, one by one. This is usually done with a metal hand file.

Then, the beads are strung up for stamping. Usually two or more silversmiths are needed for this, as the job requires both a master and an apprentice. Only a master silversmith has the expertise to make really beautiful beads, but their apprentice would be younger, with much better eyes for the job.

Lastly, the beads are cleaned, sometimes oxidized, and left to dry.

Karen Village

Thursday, February 16, 2006

Tiny Beads

Few people really understand the work that goes into making the tiny hill tribe beads that are often for sale in strands. As an example, here is a solid cube bead with a small ‘pout-duang’ (commonly known as the flower print) on it. These beads are tiny, usually measuring no more than 1-3mm each.

Subscribe to:

Post Comments (Atom)

2 comments:

Thank you for writing this. I appreciate the hard work that goes into every bead!

Thanks for sharing this lovely story! My blessings to you and the Karen!

Post a Comment